STL format

- STL (stereolithography) is a file format native to the stereolithography cad model.

- It is widely used for rapid prototyping , 3 d printing and computer aided manufacturing.

- The main purpose of the stl file format is to encode the surface geometry of a 3d object.

- It encodes this information using a simple concept called tessellation.

- Tessellation is the process of tiling a surface with one or more geometric shapes such that there are no overlaps or gaps.

- Tessellation can involve simple geometric shapes or very complicated shapes.

ASCII stl file format

file start with mandatory line:

solid <name>

file ends with mandatory line :

endsolid <name>

the file stores information about the covering triangle.

Binary stl file format

- If the tessellation involves many small triangles , the ASCII stl file can become huge.

- This is why a more compact binary version exists.

Special rules for the stl format

- The stl specification has some special rules for tessellation and for storing information.

- The vertex rule : it states that each triangle must share two vertices with its neighboring triangles.

- The orientation rule : it says that the orientation of the facet must be specified in two ways.

- The traingle sorting rule : it recommends that the triangles appears in ascending z value order.

- The all positive octant rule : it says that the coordinates of the triangle vertices must all be positive.

Advantages of stl file format

- Provides a simple method of representing 3d cad data.

- A de facto standard has been used by most cad systems and RP systems.

- It can provide small and accurate files for data transfer for certain shapes.

Disadvantages of stl file format

- The stl file is many times larger than the original cad data file.

- The geometric flaws exist in the stl file.

- The subsequent slicing of large stl files can take many hours.

Additive manufacturing technologies

- Selective laser sintering (SLS) or direct metal laser sintering.(DMLS)

- Stereolithography (SLA)

- Fused deposition modelling (FDM)

- 3d printing

- Laminated object manufacturing (LOM)

- etc

SLS and DMLS

- A laser sinters each layer of metal powder so that the metal particles adhere to one another.

- DMLS machines produce high resolution objects with desirable surface features and required mechanical properties.

- Nearly 0.1 mm thick layers.

- The part building takes place inside an enclosed chamber filled with nitrogen gas to minimize oxidation and degradation of the powdered material.

- The powder in the building platform is maintained at an elevated temperature just below the melting point and/or glass transition temperature of the powdered material.

- Infrared heaters are used to maintain an elevated temperature around the part being formed.

- A focused co2 laser beam is moved on the bed in such a way that it thermally fuses the material to form the slice cross section.

- Surrounding powders remain loose and serve as support for subsequent layers.

3D printing:

- It is an indirect process in two steps.

- After applying a powder layer on the build platform , the powder is agglomerated tanks to a binder fed through the printer nozzle.

- The operation is repeated until parts are produced, which shall be then removed carefully from the powder bed , as they are in a green stage.

- The metal part solidification takes place in a second step , during a debinding and sintering operation , sometimes followed by an infiltration step.

- It is more productive then laser beam melting andd requires no support structure. Besides it provides a good surface quality by using one of several post processing techniques.

Stereolithography (SLA)

- It uses photopolymerisation to print ceramic objects. it is also called photopolymerization.

- The process employs a UV laser selectively focused into a vat of photopolymer resin.

- The uv curable resin produce torque resistant parts that can withstand extreme temperatures.

- The source supplies the energy that is needed to induce a chemical reaction , bonding large no. of Small molecules and forming a highly cross linked polymer.

- The uv light comes from a laser , which is controlled to scan across the surface accoding to the cross section of the part that corressponds to the layer.

- The laser penetrates into the resin for a short distance that corresponds to the layer thickness.

- The first layer is bonded to a platform. which is placed just below the surface of the resin container.

- The platform lowers by one layer thickness and the scanning is performed for the next layer.

- This process is continued until the part has been completed.

Facts about SLA

- Each layer is 0.076 mm to 0.05 mm thick

- Starting materials are liquid monomer

- Polymerization occurs on exposure to uv light produced by laser scanning beam.

- Scanning speed 0.5 to 2.5 m/s

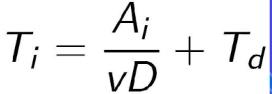

Part build time in SLA

Ai = area of layer i;

v = average scanning speed of the laser beam at the surface

D = diameter of the spot size

Td = delay time between layers to reposition the worktable.

- Time to build a part ranges from one hour for small parts of simple geometry up to several dozen hours for complex parts.

- SLA build time cycle:

where Tc = STL build cycle time ; n1 = number of layers used to approximate the part

Fused deposition modelling (FDM)

- It uses a heating chamber to liquify polymer that is fed into the system as a filament.

- The filament is pushed into the chamber by a tractor wheel arrangement and it is pushing that generates the extrusion pressure.

- The major strength of it is in the range of materials and the effective mechanical properties of resulting parts made using this technology.

- Parts made using fdm are amongst the strongest for any polymer based additive manufacturing process.

Laminated object manufacturing and ultrasonic additive manufacturing

- LOM and uam are two sheets lamination method.

- LOM uses alternate layers of paper and adhesive , while uam employs thin metal sheets conjoined through ultrasonic welding.

- LOM excels at creating objects ideal for visual or aesthetic modeling.

- UAM is a relatively low temperature low energy process used with various metals , including titanium , stainless steel and aluminium .

Electron beam melting

- The ebm process utilizes a high power electron beam that generates the energy needed for high melting capacity and high productivity . The hot process allows you to produce parts with no residual stress and the vaccum ensures a clean and controlled environment.

Selective laser melting or direct metal laser melting or laser powder bed fuion

- Materials are fully melted in DMLM and EBM processes.

- With dmlm , a laser completely melts each layer of metal .

- Ideal for manufacturing dense , non porous objects.

- A powder layer is first applied on a building platform with a recoater and a laser beam selectively melts the layer of powder. Then the platform is lowered by 20 um to 100 um and a new powder layer is applied.

- The laser beam melting operation is repeated.

- After a few thousand cycles , the build part is removed from the powder bed.

Different additive manufacturing processes:

- Powder bed fusion

- Material extrusion

- Directed energy deposition

- Material jetting

- Binder jetting

- Sheet lamination

- Vat polymerization

Powder bed fusion

- This technology is used in a variety of AM processes , including direct metal laser sintering , selective laser sintering ,selective heat sintering , electron beam melting and direct metal laser melting.

- These systems use lasers , electron beams or thermal print heads to melt or partially melt ultra fine layers of material in a three dimensional space.

- As the process concludes , excess powder is blasted away from the object.

- Spooled polymers are extruded or drawn through a heated nozzle mounted on a movable arm.

- The nozzle moves horizontally while the bed moves vertically , allowing the melted material to be built layer after layer.

- Proper adhesion between layers occurs through precise temprature control or the use of chemical bonding agents.

- Material extrusion is one of the most well known additive manufacturing processes.

- An electron beam gun or laser mounted on a four or five axis arm melts either wire or filament feedstock or powder.

- DED is similar to material extrusion , although it can be used with a wider variety of materials , including polymers ,cermics and metals.

- With material jetting a print head moves back and forth , much like the head on a 2 D inkjet printer.

- However it typically moves on a x,y and z axis to create 3d objects.

- Layers harden as they cool or are cured by ultravoilet light.

- It is similar to material jetting , except that the print head lays down alternate layers of powdered material and a liquid binder.

- LOM and uam are two sheet lamination methods.

- LOM uses alternate layers of paper and adhesive while uam employs thin metals sheets conjoined through ultrasonic welding.

- LOM excels at creating objects ideal for visual or aesthatic modelling . Uam is a relatively low temp. low energy process used with various metals , including titanium , stainless steel and aluminium.

- An object is created in a vat of a liquid resin photopolymer.

- A process called photopolymerization, cures each microfine resin layer using uv light precisely directed by mirrors.

- Thermoplastic

- Metals

- Biochemicals

- Composites

- Ceramics

- Freedom to design and innovate without penalties.

- Rapid iteration through design permutations.

- Excellent for mass customisations.

- Elimination of tooling.

- Green manufacturing

- Minimal material wastage

- Energy efficient

- Enables personalised manufacturing

- Unexpecting pre and post processing requirements

- High process cost

- Lack of industry standards

- Low speed not suitable for mass production

- Inconsistent materials

- Limited number of materials

- High equipment cost for high end manufacture

- Porosity (0.99 % density achieved)

- Aerospace

- Medical

- Manufacturing

- Automotive

- Lifestyle

- Oil and gas

- Food and beverage

- Consumer electronic

0 Comments