Basics of electromagnetic induction

- Whenever there is a change in the magnetic flux linked with the coil, an EMF is induced.

- If magnet is stationary then flux remain constant in the coil, there will not be any induction.

- If magnet is moving left side then flux will changes in the coil there will be induction.

Linear variable differential transformer

- It is a displacement sensor which is used to measure linear displacement, angular displacement.

- It works on the principle of electromagnetic induction (mutual inductance variation).

- It consists of single primary coil and two secondary coils which are connected in series opposition.

- It has movable magnetic core which couples the magnetic flux generated by primary coil to secondary coil.

Resolver

- Let us analyse the below diagram

- It is a position sensor which is able to measure linear displacement ,angular displacement.

- It works on electromagnetic induction.

- It has single primary coil which acts like rotor and two secondary coil which acts like stator.

- At each position of the primary winding the component of magnetic field is coupled with secondary windings. As a result we will get voltage at both the secondary windings.

- The ratio between the amplitude of output voltage across secondary winding provides the information shafts position.

Construction and working

- Inductosyn is a position sensor which is used to measure linear displacement ,angular displacement .

- It works on the principle of electromagnetic induction.

- It consists of two parts scale which is static and slider which is movable element .

- Scale :it has trace of conductive material which is regular rectangular shape as shown in figure.

- Slider box: it has two sliders and each slider is in regular rectangular shape as shown in figure.

- When the slider box displaces laterally on the scale then voltage will be generated across the slider because of induction .

- When the conductor of slider lies exactly above the conductor of scale then voltage generated across slider will be maximum.

- 23 conductor of scale are behaving like electromagnet.

Construction

- It consists of a rotor which rotates with rotating shaft and a coil which is winded on magnet.

- The rotor has teeth made up of magnetic material so it is called a toothed rotor.

- A transformer is used to collect the voltage from the coil.

- Electronic counter count number of pulses in second.

- Pulse frequency is used to calculate to the speed of shaft.

- The magnetic flux generated by magnetic links to the coil .

- When the rotor rotates inside the magnetic flux then the magnetic flux linked to the coil changes.

- When the teeth comes close to the coil then magnetic flux linked to the coil will be maximum as a result generated voltage is also maximum.

- Voltage generated by a coil is connected to transformer so that it can be processed further.

- Each rotor teeth when it comes close to the magnet and coil the voltage generated across the coil will be maximum and it will be considered as one pulse.

- Electronic counter counts the number of pulses in one second this information is used to measure the shaft speed.

- They are used to detect the presence of nearby objects without any physical contact.

- These sensors are capable of measuring linear displacement, angular displacement.

- These sensors find the application .

- Proximity sensors of three types :capacitive type sensor, inductive type sensor and photoelectric type sensor .

- The capacitance is increased .

- If object is not moving then capacitance is equal to Co.

- If object comes close to the fixed plate then capacitance increases.

- If object moves away from the fixed plate then capacitance decreases.

Inductive type proximity sensor

- Inductance :amount of magnetic flux linked to the coil per 1 ampere current ,if more amount of magnetic flux is linked per one ampere current then we can say that the inductance of coil is high.

- Reluctance :it is the opposition offered by medium to magnetic flux .

- If air gap increases reluctance faced by magnetic flux increases and total flux decreases therefore inductance decreases.

Photoelectric proximity sensor

- It used a beam of light to detect the presence of objects that block or reflect the light beam.

- A beam of light passes from the light source and a photo detector detects the presence or absence of light from source.

- Incandescent lamps or infrared led is may be used as light source.

- Photodiode, phototransistor are used as light detectors.

Types of stepper motor

- Variable reluctance type stepper motor

- Permanent magnet type stepper motor

- Hybrid stepper motor

- The rotor is having low mass.

- It is more responsive.

- The torque provided is low.

- It requires very low current this means it requires very low electrical power.

- It provides high torque compared to variable reluctance type stepper motor.

Application of stepper motor

- Stepper motor is used where resize positioning is required in combination with the microprocessor controller.

- It can accelerate its load easily on maximum torque occurs at low pulse rate.

- It is used in computer printers ,robotics, machine tools ,etc.

- They convert liquid air pressure into mechanical power.

- Hydraulic actuator use liquid pressure.

- Pneumatic actuator use air pressure.

- It is a device convert liquid press pressure into linear displacement or angular displacement.

- The output mechanical power depends on flow rate applied and pressure applied on piston .

- There are two types of hydraulic actuato:

- Linear actuator (hydraulic cylinder)

- Hydraulic motor (rotary actuator)

- Single acting type cylinder

- Double acting type cylinder

- Telescopic type cylinder

- Tandem type cylinder

- It can provide only one side stroke with the help of liquid pressure energy.

- Energy stored in the spring can be used to get return stroke.

- It provides two sides stroke with the help of liquid pressure energy .

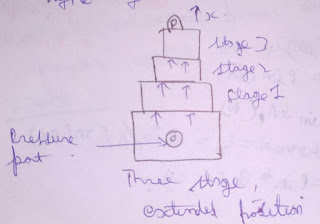

- Both extension and retraction will be done stage by stage.

- When we require large stroke length we use telescopic type cylinder.

- More than one cylinder connected in cascade configuration forms tandem type cylinder .

- It transmit heavy force without changing the dia of cylinder.

- They are the hydraulic or pneumatic equivalent of electric motors which are used when a twisting or turning motion is required.

Gear motor

Electrical actuator vs mechanical actuator

- They are portable and low power devices.

- These can be programmable hence they can be used in digital control applications.

- They provide very low output, hence cannot be used to drive heavy loads .

- Maintenance of these actuator is quite easy compared to mechanical actuator.

- These are little bit complicated to built.

- It is comparatively difficult to program.

- These provide very high mechanical output ,hence they can be used to drive heavy load also.

- Maintenance of these actuator is quite difficult.

0 Comments