Coordinate measuring machine (CMM)

- A CMM is a device for measuring the physical geometrical characteristics of an object.

- This machine may be manually controlled or it may be computer controlled.

- Measurements are defined by a probe attached to the third moving axis of this machine.

- Probes may be mechanical , optical , laser or white light , amongst others.

- A machine which takes reading in six degrees of freedom and displays these readings in mathematical form is known as CMM.

Main components

- A CMM consist of four main elements:

- The main structure which include three axis of motion .

- Probing system

- Machine control and computer hardware

- Software for three dimensional geometry axis

Main structure

1. Cantilever

- A vertical probe moves in the z axis

- Carried by a cantilever arm that moves in the y axis

- This arm also moves laterally through the x axis

- Advantage - a fixed table allows good accessibility to the work piece

- Disadvantage - the bending caused by the cantilever design

- The cantilever design offers a long table with relatively small measuring ranges in the other two axis.

- Suitable for measuring long , thin parts

2. Bridge type

Advantage:

- Most widely used

- High rigidity owing to compact bridge design and thus small measuring deviations.

Disadvantage:

- Limited accessibility caused by the bridge.

Application:

- For medium to large measuring range

3. Column type

- Often reffered to as universal measuring machine instead of cmm

- This column type cmm construction provides exceptional rigidity and accuracy

- These machines are usually reserves for gauge room rather than inspection

4. Gantry

- The support of the workpiece is independent of the x and y axis , both are overhead , supported by four vertical column rising from the floor.

- This setup allows you to walk along the workpiece with the probe , which is helpful for extremely large pieces.

5. Horizontal

- Also referred to as layout machine .

- Has a moving arm and the probe is carried along the y axis

- Advantage - provides large area

- Ideal configuration of measurement of automobile parts.

Probing system

- It is the sensory part of the cmm responsible for sensing different parameters required for the measurements.

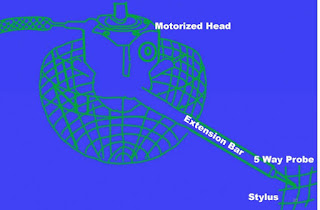

Stylus:

A pointed instrument used as an input device in the probe of a CMM

Types of probe:

- Transmission trigger probes

- Optical transmission probes

- Motorized probes

- Multiple or cluster probes

- Proximity or non contact probes

Inductive transmission probes

- They have been developed for automatic tool changing.

- Power is transmitted using inductive linking between modules fitted to the machine structure and attached to the probe.

- These probes also have been developed for automatic tool changing .

- It allows probe rotation between gaging moves , making it particularly useful for datuming the probe.

- The wide angle system allows greater axial movement of the probe and is suitable for the majority of installation.

Motorized probe

- With the motorized probe , 48 positions in the horizontal axis , 15 in the vertical axis can be programmed for a total of 720 distinct probe orientation .

- A range of light weight extension , the head can reach into deep holes and recesses.

- The head of the probe is sufficiently compact to be regarded as an extension of the machine quill.

- This enables the inspection of complex components that would otherwise be impossible or involve complex setups.

Multiple stylus probe heads

- Wide range of styli have been developed to suit many different gaging applictions.

- The selection of stylus is done based on the application for which the probe is to be used .

Proximity or non contact probes

- Uses laser , capacitive or video measurement technology.

Laser probe

- A cmm equipped with a laser probe can convert a part of physical model into a digitized file.

- Such a file can be compared with other files and can be manipulated by designers to improve quality.

- Manufacturers can verify that each finished part measures exactly as designed.

- Laser triangulation probes are used to scan the surface and after scanning it transmits a continuous flow of data .

- Line lasers are the fastest way to inspect non linear surface .

- It is widely used in reverse engineering.

Automatic stylus change system

Machine control and computer hardware

- The control unit allows manual measurement and self teach programming in addition to cnc operation .

- The control unit is microprocessor controlled .

- Usually a joystick is provided to activate the drive for manual measurement.

Software for three dimensional geometry analysis

- In a cmm , the computer and the software are an inseparable part.

- They together represent one system

- The efficiency and cost effectiveness of a cmm depend to a large extent on the software.

The features of CMM software

- Measurement of diameter , center distance , length , geometrical and form errors in prismatic components, etc.

- Online stastics for statistical information in a batch.

- Parameter programming to minimize cnc programming time of similar parts.

- Measurements of plane and spatial curves.

- Data communication

- Digital input and output commands for process integration

- Program for the measurement of spur , helical , bevel and hypoid gears.

- Interface to cad software

Working principle of CMM

- CMM is also a device used in manufacturing and assembly processes to test a part or assembly against the design intent .

- By precisely recording the x , y , z coordinates of the target point are generated which can then be analyzed via regression algorithms for the construction of features.

- These points are collected by using a probe that is positioned manually by an operator or automatically via direct computer control.

Modes of operation

1. Manual mode:

- CMM has a free floating probe .

- The operator moves the x,y,z axes to establish contact with the part feature to be measured .

- The differences in scale reading among the contact points are the measurements.

2. Manual computer assisted:

- Electronic digital displays are added to cmm for making zero setting, to select inch/mm , to print data in the standard format.

- These features save time , minimize calculations and reduced errors.

- A joystick is used to drive the machine axes.

- The operators manipulates the joystick to bring the probe into contact with the job.

3. Direct computer controlled:

- This is fully programmable

- The cmm uses 'taught' locations of cad data , to decide where the probe contact the job, and then collects measurement data.

- The fully automated cmm allows the operator to place the job in a fixture or on a table . run a stored program , collect the data points, and generate an output report/SQC record.

Advantages of CMM

- Flexibility

- Reduce setup time

- Single setup

- Accuracy

- Reduce operator influence

- Improve productivity

- Universatility and ease of operation

Application of CMM

- Aerospace engineering

- Automobile engineering

- Reverse engineering

- Medical engineering

CMM in computer aided manufacturing

DMIS

- Dimensional measurement interface specification is a new standard in communication being used in CAM.

- It provides a bi-directional communication of inspection data between CAD system and inspection equipment so as to see what has to be made.

0 Comments